The Legacy of Skyline Plaza: Revolutionizing Concrete Strength Assessment

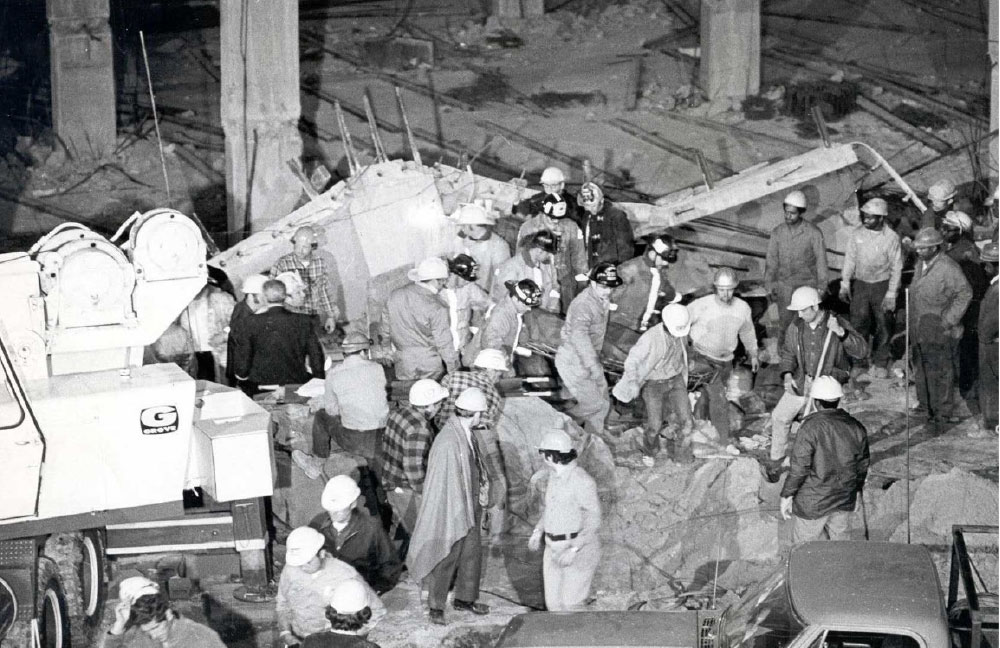

In March 1973, the 26-story Skyline Plaza condominium building, under construction in Bailey’s Crossroads in Fairfax County, Virginia, collapsed, killing 14 construction workers and injuring 35 others.

The collapse of the Skyline Plaza in Virginia in 1973 was a turning point in construction history. It brought to light the vulnerabilities in construction practices and paved the way for groundbreaking advancements in concrete technology. One such advancement was the development of concrete maturity assessment, a method that fundamentally transformed how the construction industry evaluates the strength of in situ concrete.

The collapse of the Skyline Plaza in Virginia in 1973 was a turning point in construction history. It brought to light the vulnerabilities in construction practices and paved the way for groundbreaking advancements in concrete technology. One such advancement was the development of concrete maturity assessment, a method that fundamentally transformed how the construction industry evaluates the strength of in situ concrete.

Prior to the Skyline Plaza incident, the construction industry relied heavily on standard curing times and rudimentary testing methods to estimate concrete strength. In the cold North American winters This approach was fraught with uncertainties, often leading to premature formwork removal or overstressing of freshly poured concrete. The Skyline Plaza tragedy underscored the need for a more reliable and scientific method to assess in-situ concrete strength in real-time.

The National Bureau of Standards (NBS) investigators concluded that the cause of the collapse was that the field concrete had insufficient strength at the time the shoring was removed. The concrete slab at the location where the failure started was 4 days old and had been exposed to an average ambient temperature of about 7°C (compared to the temperature of 23°C to which standard cured concrete cylinders would be exposed). This disaster led to the development of maturity methods for estimating the field strength of concrete to help prevent similar structural failures.

In response to the need to assess concrete strength in real-time, the concept of concrete maturity assessment was developed. This method correlates the temperature history of concrete to its strength development, offering a more accurate and real-time assessment of concrete’s readiness to bear loads. This approach marked a significant departure from traditional methods, offering a blend of science and practicality that was previously absent.

Since its inception, concrete maturity assessment has become integral to modern construction practices. It is not just a method but a standard for safety, efficiency, and quality in construction. From skyscrapers to bridges, this method ensures that every concrete structure stands the test of time and load.

The implementation of Concrete Maturity Assessment offers many benefits, such as:

- Increased Safety: By providing accurate, real-time data on concrete strength, the maturity method greatly reduces the risk of structural failures like that of Skyline Plaza.

- Efficiency in Construction: With reliable data on hand, construction schedules can be optimised, reducing wait times and increasing productivity.

- Quality Assurance: The maturity method ensures that concrete achieves the desired strength before any load is applied, enhancing structures’ overall quality and durability.

- Cost-Effectiveness: Reduced testing and fewer delays translate to significant cost savings for construction projects.

Here’s a bit more detail on how concrete maturity works:

The core principle behind concrete maturity is that the strength development of concrete is a function of both time and temperature. As concrete cures, the chemical reaction known as the hydration process causes the material to harden and gain strength. These reactions are influenced by temperature. The higher temperatures accelerate the hydration process. Similarly, colder temperatures slow the hydration process.

Maturity Index: The maturity of concrete is quantified using a maturity index. This index is a numerical value representing time and temperature’s effect on curing. The most common maturity functions are the Nurse-Saul function (based on the principle that strength gain is proportional to the product of age and average temperature) and the Arrhenius equation (which incorporates a more complex relationship between temperature and strength gain).

Temperature Monitoring: To apply the maturity method, the temperature of the concrete must be monitored from the time it is placed. This is usually done using embedded temperature sensors. These sensors record the temperature of the concrete at regular intervals.

Data Analysis: The recorded temperature data is then used to calculate the maturity index. This involves integrating the temperature over time, either using a simple cumulative method or a more complex function that accounts for the specific rate of strength gain at different temperatures.

Strength Estimation: A relationship between strength and maturity must be established to translate the maturity index into an estimate of concrete strength. This is typically done through laboratory tests on the specific concrete mix being used. Samples are cured at different controlled temperatures, and their strength is measured at various points. This data then creates a maturity curve or formula that correlates the maturity index to concrete strength.

Practical Application: In a construction setting, once the maturity index is calculated, it can be compared to the established maturity curve to estimate the concrete’s current strength. This allows construction managers to make informed decisions about when to remove formwork, apply load, or move to the next stage of construction.

Technology Integration: Modern approaches often integrate technology such as wireless sensors and real-time data analysis software to monitor concrete maturity, providing more accurate and timely information for construction decision-making.

Overall, concrete maturity is an important concept in construction, enabling more accurate and efficient monitoring and management of concrete curing and strength development.

References

U.S Department of Commerce. (2023). National Institute of Standards and Technology. Retrieved from Skyline Plaza Collapse in Fairfax County: https://www.nist.gov/publications/investigation-skyline-plaza-collapse-fairfax-county-virginia-nbs-bss-94

Wikipedia. (2023, September 17). Skyline Towers collapse. Retrieved from https://en.wikipedia.org/wiki/Skyline_Towers_collapse